Guandiaocnc

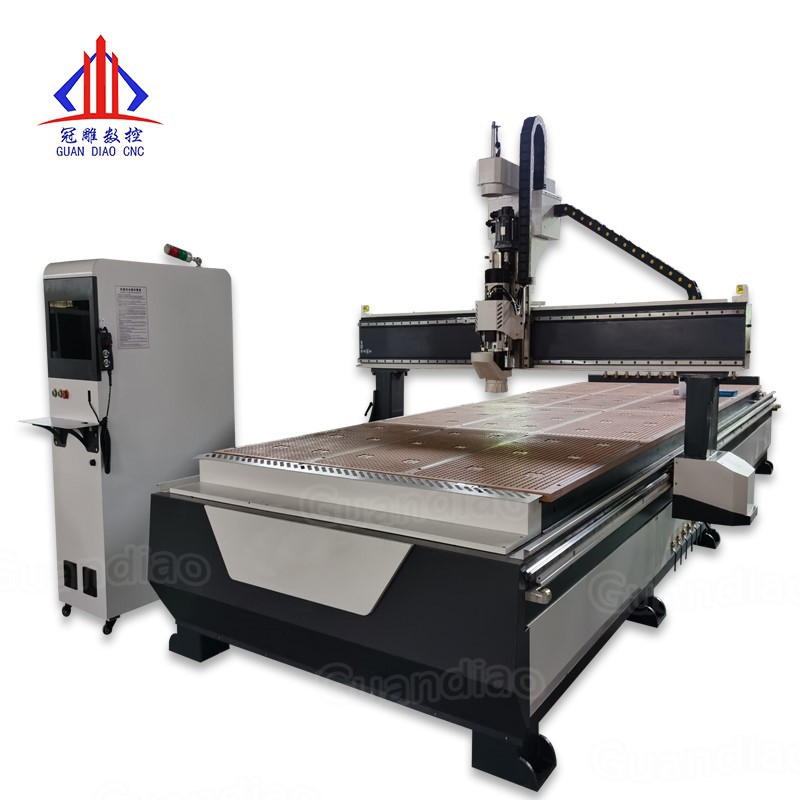

1. Three-in-one cabinet assembly

Only the cabinet body is processed, and the cabinet body is assembled using three-in-one. It is recommended to choose a four-process CNC woodworking cutting machine. The four-process CNC woodworking cutting machine can realize the automatic switching of four knives, which can fully meet the processing technology of general cabinet cutting, punching and grooving.

Reduce Labor Costs

Precision Cutting

Computer Control

Cutting/Drilling

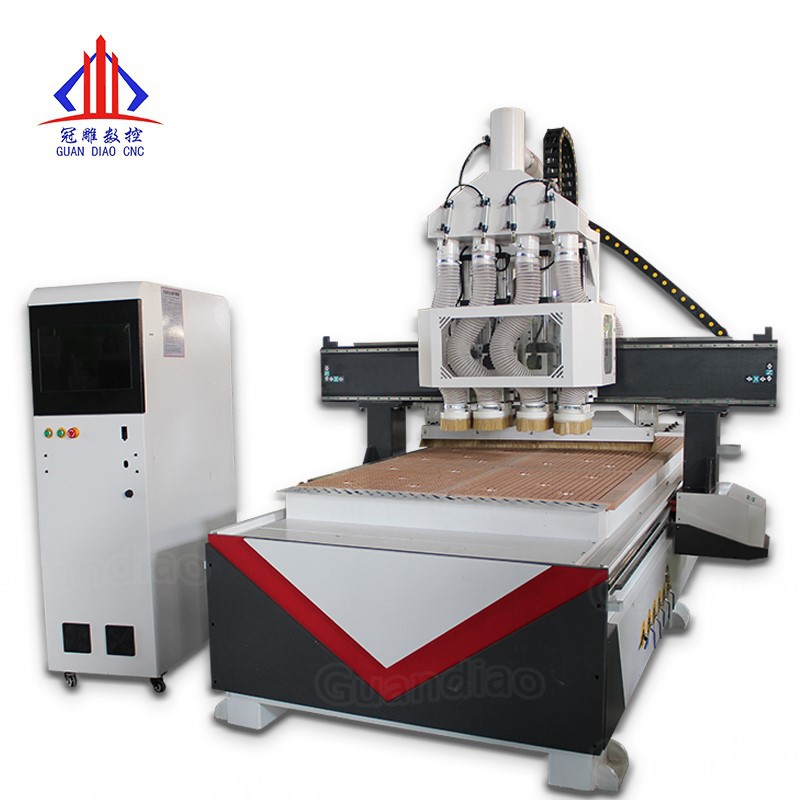

2. Cabinet door (plastic door) cabinet processing

The cabinet body and door are all made. It is recommended to select a straight row automatic tool change CNC woodworking material opener. It can realize automatic switching of 12 knives, which can not only meet the requirements of cutting and grooving the cabinet door, but also meet the requirements of carving and processing of complex patterns

Four-step multi-spindle design is more reasonable, fast processing speed, simple maintenance, low fault

Equipped with a 10-12 tool linear tool magazine, which can quickly and freely change tools. Change tools within 5 seconds.

CNC router can add machine functions as required

Automatic lubrication system, independent chassis, vacuum adsorption table.

The machine can automatically complete the work of feeding, punching, engraving, cutting and unloading, which can greatly save labor costs and improve processing efficiency. It is an indispensable helper in the panel home industry.

Optional automatic typesetting software, only need to input the sheet size, the software optimizes its typesetting, the sheet usage efficiency can reach more than 90%, improve the sheet usage efficiency and reduce the cost of raw materials.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb