Guandiaocnc

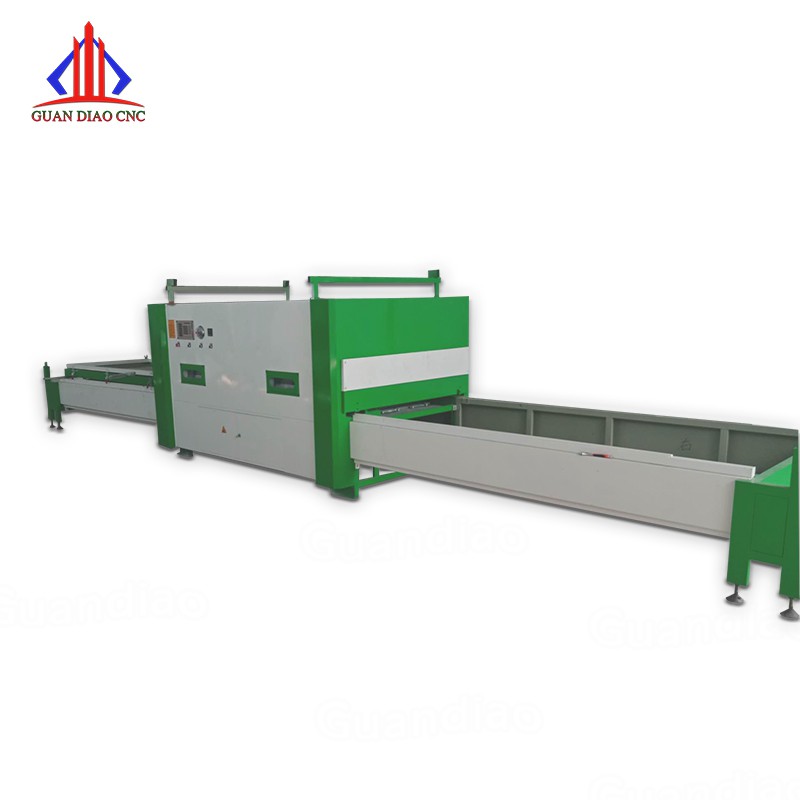

The skinning process can be done semi-automatically or automatically by intelligent setting (instructions for ordering requirements).

Easy to operate. high degree of automation.

The high-efficiency constant temperature heating system is adopted, and the temperature rises quickly and the heat preservation time is long. Save energy, save time and electricity. Heat evenly.

The key components of the electric control system are equipped with high temperature resistant and high insulating materials, and the operation is safe and reliable.

Classification difference

Vacuum must be a negative pressure state. Negative pressure is a state below atmospheric pressure, and vacuum in physical theory refers specifically to the state of space without any substance, which is an ideal state of space, but vacuum in industrial applications refers to when the pressure in the container is low At atmospheric pressure, the part below atmospheric pressure is called vacuum, and the pressure in the container is called absolute pressure; another way of saying is that the space in the container whose pressure is lower than atmospheric pressure is called vacuum

Vacuum laminating machines are divided into single-table and double-table laminating machines. According to the function of the machine, from a professional point of view, it is recommended to use a laminating machine with double working surfaces, which can complete the laminating work more quickly. However, it requires a relatively large space. If you have space requirements, you can choose a machine with a single work surface.

Our advantage

The double-station laminating machine has two workbenches, which greatly improves the working efficiency of the machine and effectively guarantees the output; the workbench is driven by a power motor to enter and exit the heating box, automatic plastic forming, automatic heating, automatic pressurization, and the degree of automation Higher, easier and more convenient to operate.

The working surface of the laminating machine body is made of high-strength steel plate, which will not deform under high temperature, effectively ensuring the flatness and stability of the workpiece.

The operating table adopts an independent electrical box, which makes the operation simpler and more direct, and the working conditions are easier to control. Even if there is a temporary failure, manual operation can also be used without delaying production.

The heating method of the double-station laminating machine has been improved from the original electric heating to heat dissipation plate heating, so that the temperature difference on the surface of the material can be less than 5°C, and the surface smoothness of the film-coated finished product has been greatly improved and improved, and there will be no Orange peel, bubbles, etc., are more suitable for lamination of high-gloss film, matte film and skin-feeling film.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb