Guandiaocnc

The edge banding machine is a kind of woodworking machine, which is a real wood machine. As the name implies, the edge banding machine is used for edge banding. The traditional manual operation process is completed by a highly automated machine, including a number of processes, such as conveying, gluing, edging, cutting, front and back edge trimming, upper and lower edge trimming, upper and lower fine trimming, upper and lower edge scraping, polishing and so on.

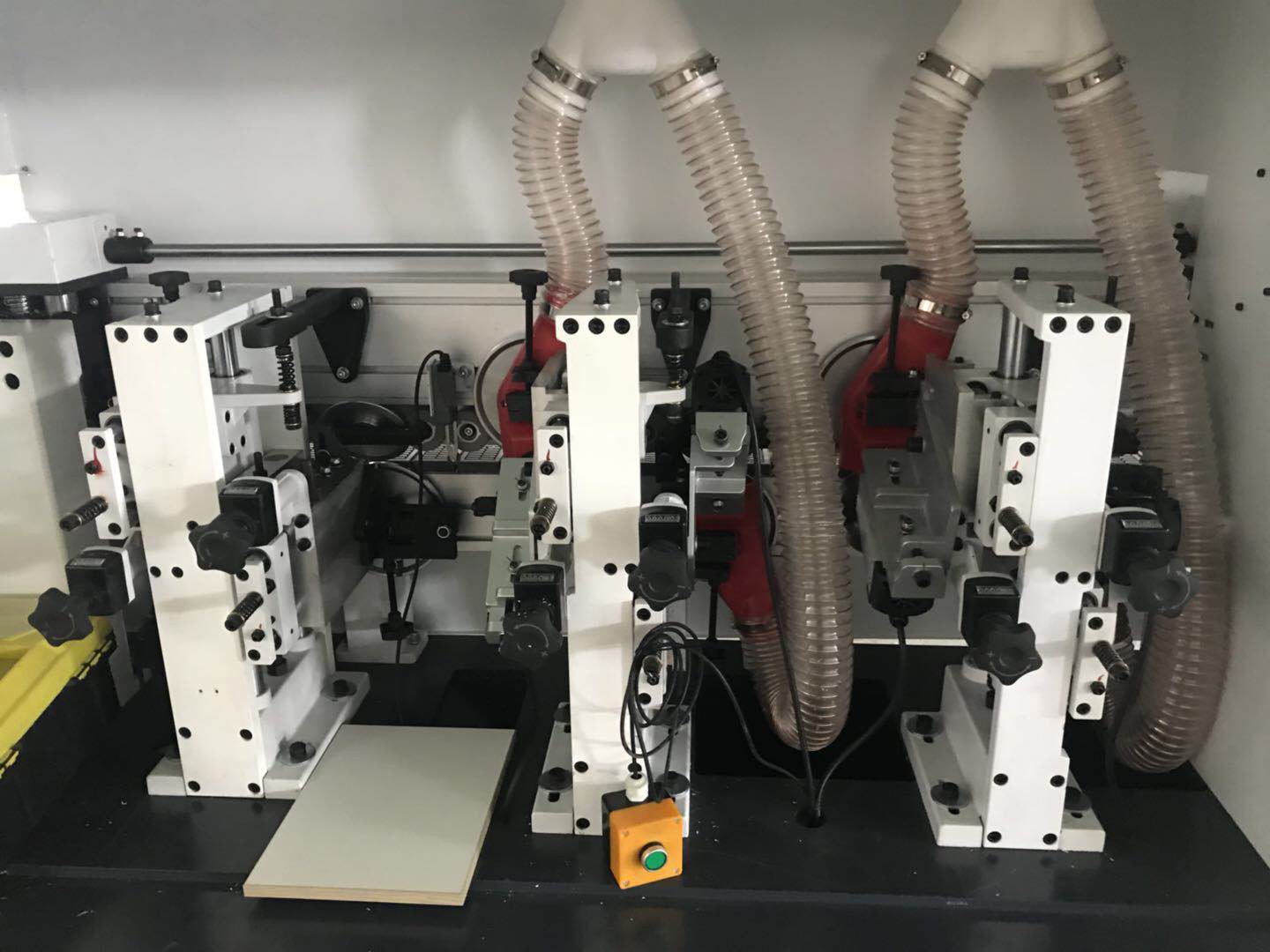

Pre-milling: the double-milling cutter is used to modify the ripple marks, burr or non-vertical phenomenon caused by the cutting saw, so as to achieve better edge sealing effect, so as to make the combination between the edge banding strip and the plate closer, with better integrity and aesthetics.

Gluing and edge sealing: through special structure, both sides of the edge sealing plate and edge sealing material are evenly glued to ensure stronger adhesion.

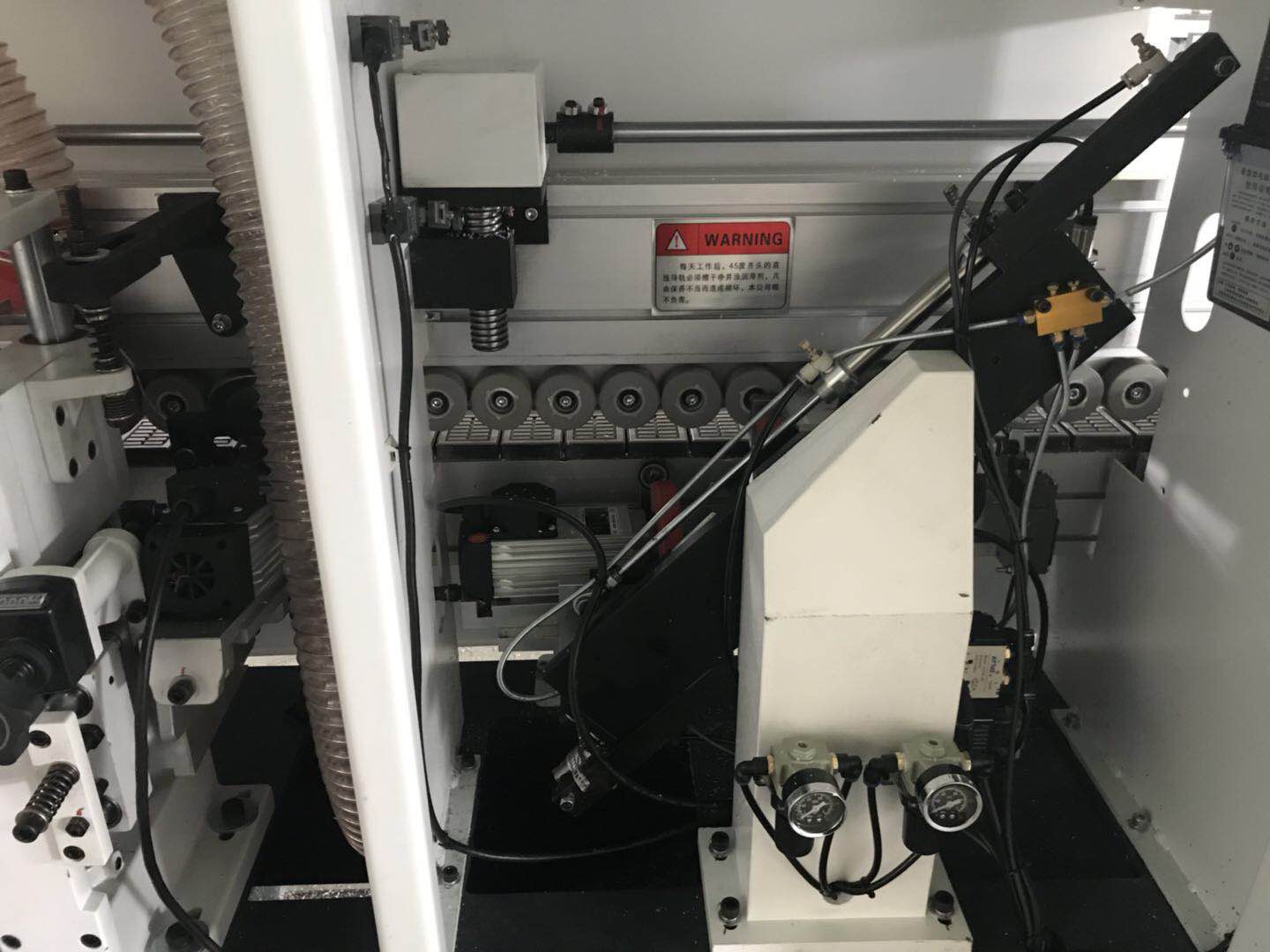

End trimming: through the movement of the linear guide rail, it adopts the structure of profiling automatic tracking and high frequency high speed motor fast cutting to ensure that the cutting surface is flat and smooth.

Trimming: It is used to eliminate the ripple marks generated during non-linear trimming and cutting, and make the upper and lower parts of the plate more smooth and tidy.

Polishing: clean the processed plate with a cotton polishing wheel, and make the edge sealing end face more smooth through polishing.

Slotting: It is used to slot the side plate and bottom plate of the wardrobe directly, which is more convenient and faster, and reduces the process of sawing; It can also be used for slotting the aluminum edge of the door panel

Operation process

1 Please check and clean the sundries on the machine before starting;

2 Please remind the surrounding staff to pay attention to safety when starting the machine;

3 Check the residual amount of hot melt adhesive before heating the heating gluing box.

4 Non-professional personnel are forbidden to open the control box and electric control cabinet;

5 Before replacing electrical components, please cut off the power supply of the machine;

6 Please carry out maintenance and repair in the shutdown state.

7. The places marked with yellow (red) color are high-temperature objects, electrified objects, or high-speed rotating tools, please pay special attention;

8 In case of any abnormality during processing, please immediately press the emergency stop switch;

9 When placing the edge banding belt, its head should pass through the belt pulley and not exceed the cutting knife, otherwise it may cause damage to some mechanisms when sealing the first plate

New control panel, Taiwan delta touch screen control, one button operation, Korea Otoni temperature controller, accurate temperature control, more durable.

The end trimming is through a precise guide track movement, and it adopts the automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb