Guandiaocnc

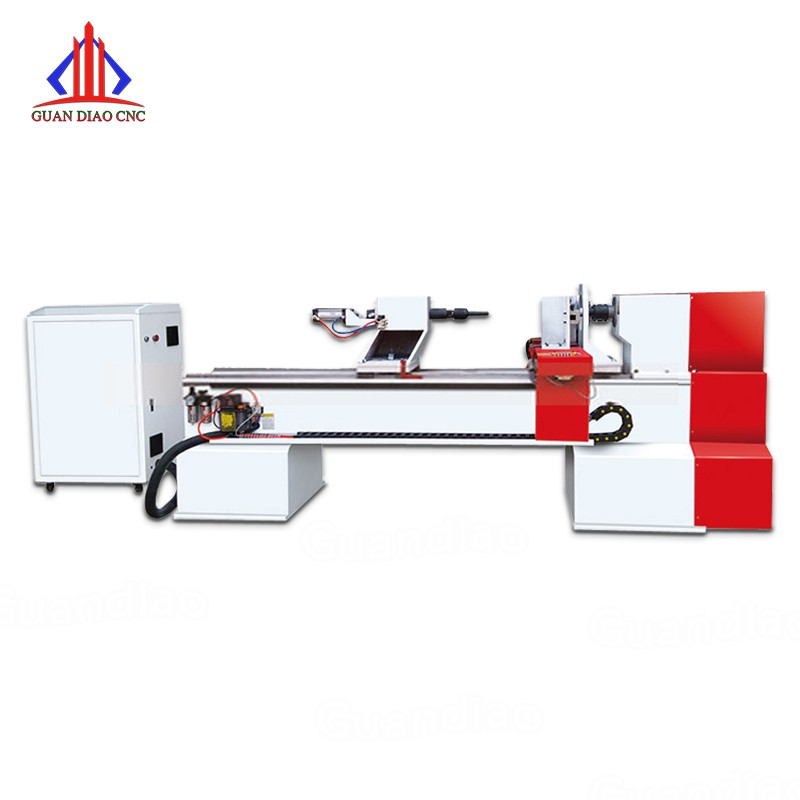

The left end bed of the saddle lathe at the headstock is sunken and can accommodate parts with large diameter. The shape of the lathe is high at both ends and low in the middle, which looks like a saddle, so it is called a saddle lathe. Saddle lathe is suitable for machining parts with large radial size and small axial size, and is suitable for turning the outer circle, inner hole, end face, groove and metric, inch, module and pitch thread of the workpiece. It can also carry out drilling, boring, reaming and other processes, especially for single piece and batch production enterprises. The saddle lathe can process large diameter workpiece in the saddle groove. The guide rail of the machine tool is hardened and polished, which is convenient and reliable to operate. The lathe has the characteristics of large power, high speed, strong rigidity, high precision and low noise.

1. Large low-frequency torque and stable output

2. High performance vector control

3. Fast torque dynamic response and high speed stability accuracy

4. Slow down and stop fast

5. Strong anti-interference ability

The saddle lathe has all the structural and performance characteristics of the base product, and is made of a saddle attached to the bed, which expands the processing range of the machine tool. The saddle of the machine tool is easy to disassemble and has high repeated positioning accuracy. After disassembling the saddle, special shape parts and large diameter disc parts can be processed. This machine tool is widely used for single piece or batch production in various mechanical processing industries, and is also a suitable supporting equipment for scientific research institutions.

The main components of an ordinary lathe are: headstock, feed box, slide box, tool rest, tailstock, smooth screw, lead screw and bed.

Spindle box: also known as headstock, its main task is to transmit the rotating motion from the main motor to the feed box through a series of variable speed mechanisms to make the spindle obtain the required different rotational speeds of the positive and negative directions. Spindle in headstock is the key part of lathe. The smoothness of the spindle running on the bearing directly affects the processing quality of the workpiece. Once the spindle rotation accuracy is reduced, the use value of the machine tool will be reduced.

Feed box: also known as tool feed box. The feed box is equipped with a speed change mechanism for feed movement. Adjust its speed change mechanism to obtain the required feed amount or pitch, and transmit the movement to the tool holder through the smooth screw or lead screw for cutting.

|

|

|

Lead screw and smooth screw: used to connect the feed box and the chute box, and transmit the motion and power of the feed box to the chute box, so that the chute box can obtain longitudinal linear motion. The lead screw is specially set for turning various threads. When turning other surfaces of the workpiece, only the bare screw is used instead of the lead screw.

Slide box: It is the control box for the feed motion of the lathe, which is equipped with a mechanism to change the rotation motion of the smooth screw and the lead screw into the linear motion of the tool holder. The longitudinal feed motion, the transverse feed motion and the rapid movement of the tool holder are realized through the smooth screw transmission, and the lead screw drives the tool holder to make the longitudinal linear motion, so as to turn the thread.

Tool holder: The tool holder component is composed of several layers of tool holders. Its function is to clamp the tool and make the tool move longitudinally, transversely or diagonally.

Tailstock: install the rear center for positioning support, or install drill bits, reamers and other hole processing tools for hole processing.

Body: The main parts of the lathe are installed on the bed, so that they can maintain accurate relative positions when working.

Factory

Machine Show

Office Show

Exhibition Show

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb