Guandiaocnc

Polishing machines, also known as grinders, are often used for mechanical polishing, polishing, and waxing. Polishing machines can be divided into automatic polishing machines, industrial polishing machines, and handheld polishing machines; Manual polishing machine: mainly composed of a base, spindle head, polishing column, frequency converter, motor, transmission mechanism, and tensioning mechanism. The polishing machine can be matched with thousand leaf grinding wheels, hemp wheels, nylon wheels, cloth wheels and other wheels to perform surface processing on various materials of workpieces, in order to achieve different effects, such as rough polishing, intermediate polishing, and precision polishing. The advantage of a handheld polishing machine is that it is more flexible for manual handling of products, and can polish off the dead corners of some products. However, there are also some drawbacks, such as high labor management costs, unstable polishing quality, poor polishing environment, easy inhalation of dust by workers, and product efficiency determined by people's mood.

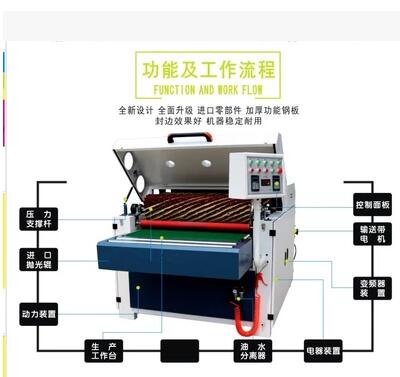

With the deepening of industrialization and the gradual disappearance of population dividends, labor costs have significantly increased, and raw material prices have continued to rise. In combination with user needs, our company is committed to providing customers with higher quality and cost-effective products in product development and design, such as rotary polishing machines. The rotary polishing machine is a widely applicable equipment that can perform fast and high-quality processing on cylindrical and conical workpieces made of copper, iron, zinc, and stainless steel. The machine can operate intermittently or continuously, and the disc is controlled by a frequency converter and a motor. According to the different process requirements of polishing products, different polishing machine heads with different functions, specifications, and quantities are selected from each series, and polishing wheels with different functions and applicable are selected to achieve polishing effects such as sanding, rough polishing, medium polishing, and fine polishing. Our polishing machine components and accessories are all from top tier brands with high quality, safety, and reliability. The mold has high concentricity, high fit with the product, and better polishing effect. Parameterized management, torque is parameterized for easy management, equipped with automatic fault alarm function, and can automatically display the cause of faults through the touch screen. This model is easy to operate, convenient, and has stable quality, which can effectively reduce labor costs and dust hazards.

Today's fully automatic polishing machines: efficient, dust-free, no need for polishing workers, simple and easy to operate, efficient work

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb