Guandiaocnc

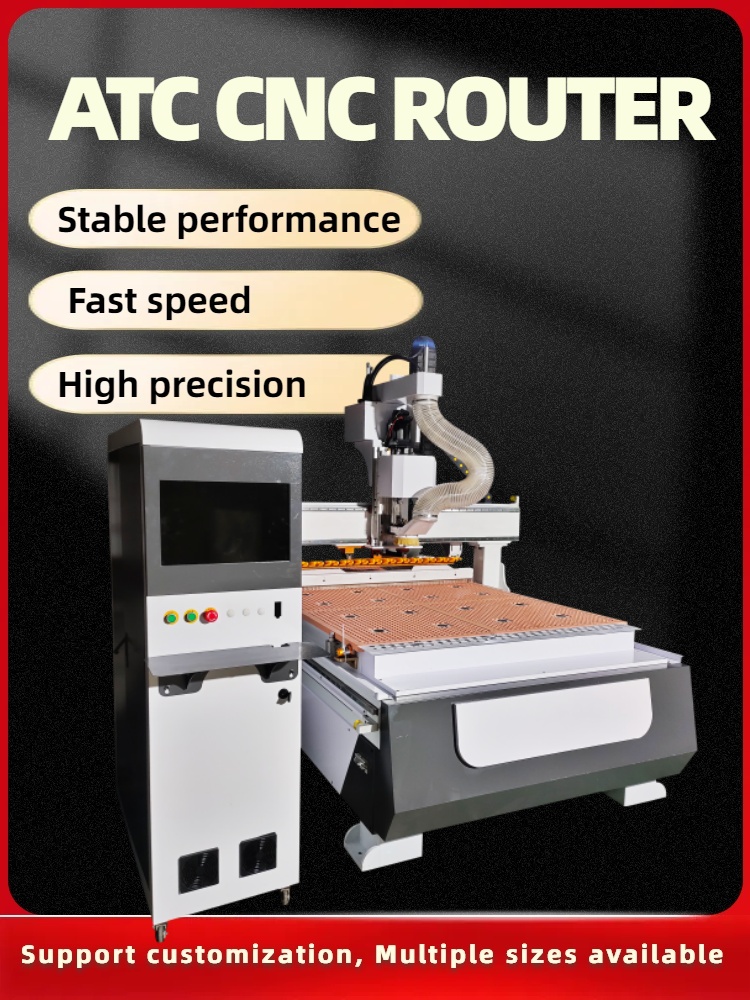

ATC CNC Router is a major category of CNC CNC Router and represents the most advanced engraving machine equipment. It has an independent tool library that can automatically replace the required tools during machining of the workpiece without stopping the work. When carving complex patterns, choosing different cutting tools greatly accelerates work efficiency and improves product quality. Automatic tool changing CNC Router are also CNC controlled

The ultimate trend in the development of carving machine equipment.

This model is also the preferred choice for large enterprises and those with high activity. It uses two 7.5KW air-cooled motors and two main axes with different cutting tools. This model is mainly suitable for multi tool forming workpieces and adopts advanced Weihong automatic control software, which can achieve automatic switching between the two axes and greatly improve work efficiency.

This high-speed engraving machine series is a Y-axis dual motor driven CNC engraving machine. Three axis gear rack transmission has excellent accuracy and cost-effectiveness.

1. Adopting a gantry high steel structure; The crossbeam is made of 150 * 150 * 8 materials, ensuring that it does not deform during aging treatment;

2. The entire machine is welded with rectangular steel pipes, and is precision processed after annealing and stress relief heat treatment; 3. Use a stationary countertop and a movable gantry.

Adopting Y-axis dual motor drive technology

The use of Y-axis dual motor dual drive technology greatly improves the vibration resistance of the machine tool's three axes, reducing vibration by nearly 10 times. Due to the use of dual motor drive, the tilting of the gantry during movement is reduced, the contour machining accuracy is improved, the surface roughness can be reduced by half, and the acceleration of the machine tool shaft can also be increased by 20%, which is equivalent to the working efficiency of 3-5 similar equipment.

Imported linear guide rail 1. All three axes are driven by imported linear guide rail rack and pinion;

2. All three axes use imported 25mm linear guides, and we only use the best quality linear guides such as HIWIN and Intime. Although these high-quality components are more expensive than other components, excellent quality is the only way to achieve the high precision and long lifespan required by users.

Feed drive system

The feed drive adopts a stepper high-speed motor and microstep subdivision technology, with fast speed and low vibration.

Spindle drive system

The spindle drive adopts Fuling variable frequency control; High speed water-cooled variable frequency spindle.

1. Adopting high-speed chuck and high-speed nut, suitable for high-speed machining; 2. After strict dynamic balancing, it meets the requirements of high speed.

Drag chain system

The cost of using flexible cables and drag chains is obviously much higher than using ordinary cables and drag chains. But it can ensure the reliability of the machine. The machine tool is constantly in motion, and the cables are repeatedly twisted. Generally, cables are prone to breakage, leading to inexplicable malfunctions and extremely difficult to repair. We use a fully enclosed drag chain system to ensure the absolute safety of the cables.

Introduction to Vacuum Adsorption Table Performance 1. The table adopts a vacuum adsorption table, made of hard PVC, which is resistant to high temperature and corrosion, and can strongly adsorb materials of different areas.

2. The vacuum adsorption table is divided into 12 areas, which can be divided according to customer requirements. It can be processed in a single area or simultaneously to improve processing efficiency.

3. 7.5KW water circulation vacuum pump, high adhesion vacuum adsorption device can achieve a displacement of 400 hours. The maximum vacuum degree can reach -0.086MPa

Humanized design of the countertop, which can both adsorb and clamp workpieces, making it convenient to use

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb