Guandiaocnc

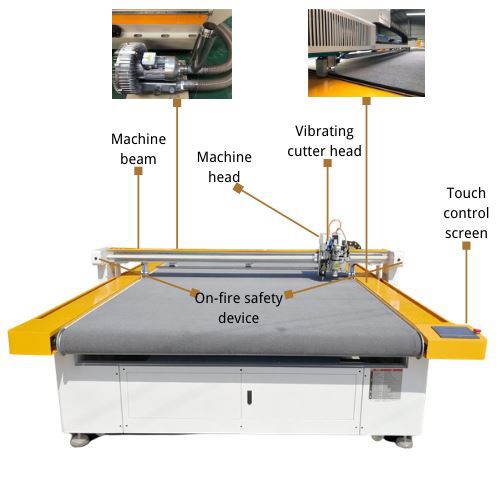

Vibrating knife cutting machine: When cutting, it will vibrate, tens of thousands of vibrations per minute, similar to the principle of the saw blade, but no zigzag, no powder, the vibrating knife can be free to replace the cutter head, according to different materials, you can choose Round knife, semi-cut knife, tower, diagonal knife, milling cutter, etc.

The finished product cut by the vibrating knife cutting machine is also clean and neat, with smooth edges, and the size of the cut pieces is accurate, odorless, relatively environmentally friendly, soft and hard materials are available, and the foot cushion leather modification system is well used.

The cutting speed of the vibrating knife cutting machine is twice that of the rotary knife, and the equipment is widely used, such as the clothing industry and the advertising industry. It is also the first choice of many companies. The disadvantage is that the price may be higher. Of course, if the initial budget is sufficient, there is no problem at all.

Note for vibrating knife cutting machine:

1. When moving the working table of the vibrating knife cutting machine, the moving speed should be correctly selected according to the distance to the workpiece, and avoid collision when moving too fast.

2. When programming, determine the correct processing technology and processing route according to the actual situation, and prevent the workpiece from being scrapped or cut off in advance due to insufficient processing position or insufficient edge strength.

3. It is necessary to confirm whether the program and compensation amount are correct before thread cutting.

4. When starting the cut, pay attention to observe and judge the processing stability of the vibrating knife cutting machine, and adjust it in time when it is found to be defective.

5. During the processing of the vibrating knife cutting machine, the cutting conditions should be inspected and supervised frequently, and the problems should be dealt with immediately.

Performance characteristics of vibrating knife cutting machine:

1. Imported multi-axis, multi-channel control system is adopted, which has the characteristics of high response, high anti-interference and high stability.

2. The design concept of replaceable heads is adopted, and the tool heads are not fixed and integrated, and tool heads with different functions can be easily replaced and added according to actual work needs and business scope expansion;

3. The servo motor drives the lead screw control mode, and the computer linkage can preset and store the knife deep knife pressure according to different needs. Compared with the old-style pneumatic head, it completely bids farewell to the history of manually adjusting the knife deep knife pressure based on experience. It is convenient Digital fine-tuning can also completely solve the problem that the aerodynamic pressure fluctuates with temperature and time and cannot be constant;

4. The controller has been upgraded from the era of computer motherboard plug-in cards to the era of high-performance integrated circuit controllers. It can be connected to any ordinary computer (including notebooks) without special high-end computers. If the computer fails, it can be easily replaced. The computer is used to operate the equipment, which completely eliminates the paralysis of the cutting equipment caused by the failure of the computer link;

5. Taking into account the actual use environment factors of the customer, specially equipped with anti-interference operation screen, which will not be affected by the surrounding electronic environment during work, and will not flicker the screen;

6. The data interface is a network interface, which can realize remote upgrade and maintenance. The transmission speed is fast and the distance is long. It can be transmitted with multiple computers at the same time. It can be remotely controlled and upgraded. Compared with the old serial port, parallel port, PCl interface, it is more advanced. more convenient;

7. Equipped with various tools such as vibrating knife, drag knife, round knife (optional driving wheel knife, pneumatic round knife) and drawing pen tools, depending on the different requirements of different materials, it can realize such as writing and drawing lines, cutting of dotted lines, Half-cut cutting, full-cut cutting and other functions, it can cut various flexible materials such as sponge composite, XPE material, silk ring, leather, soft glass, silica gel, rubber material, etc.

8. It can complete the touch cutting, indentation and forming of flexible materials such as leather, paper and plastic without knife molds and die cutting machines, which can save a lot of manpower, knife molds and die cutting machine costs. Instead of the traditional paper manual development design and proofing, shorten the corresponding research and development time; in order to meet the customers' production goals of small batches, more orders, and more styles, a set of standardized and feasible complete solutions are created.

9. Rolling table equipment, the width of the platform can be customized, and the theoretical cutting length is unlimited. It is suitable for automatic feeding and cutting of coils and plates. It saves labor and configures multi-functional cutting tools, which is convenient for marking complete sets of materials, easy to find, and convenient to produce

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb