Features

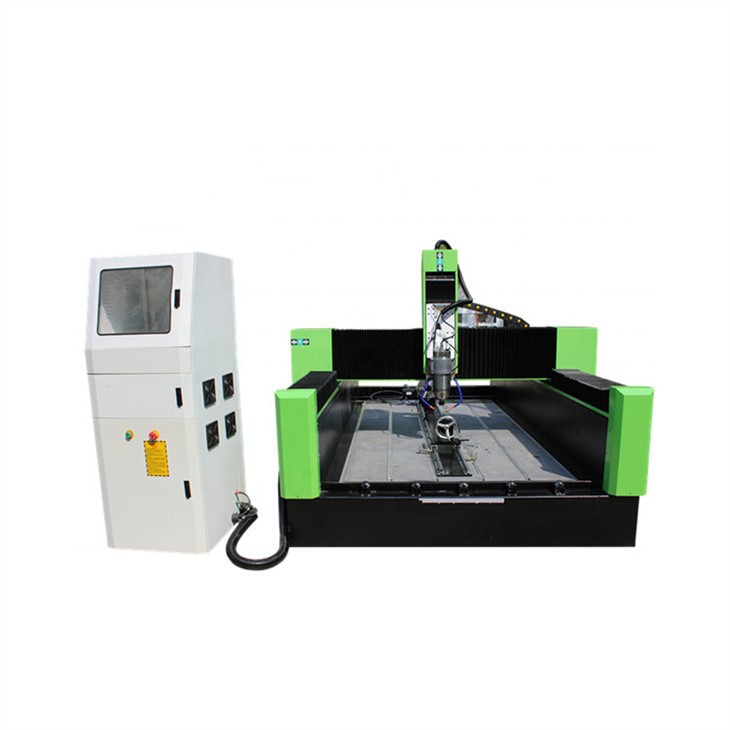

A. Whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the lathe body is stabilized and will not be deformed forever.

B. Three axes adopt Taiwan HIWIN linear guide rail with high precision. Z axis adopts imported Taiwan made ball screw, so high precision and long life time using are assured.

C. Yaskawa servo system and reducer to make sure speed and stability. YASKAWA servo motors runs smoothly, no vibration phenomenon even in low speed and has overload ability, servo is more reliable and better than stepper.

D. X and Y axis is transmitted by helical rack and pinion. This makes the machine work faster and has larger cutting force compared with ball screw transmission.

E. Well compatibility: CAD/CAM designing software, such as type3/ucancam/artcam, etc.

F. This machine has the function of re-carving after break point or power failure and it can estimate the processing time.

G. Manual/automatic oil-injection system allows the machine maintenance mush easier.

Product Specification

Name | Granite engraving machine |

Working size | 1300*2500mm |

Max feeding height | <300mm, (Customized) |

Max travelling speed | 6000-10000mm/min |

Tool diameter | ¢3, ¢4, ¢6, ¢8, ¢12.7, etc |

Transmission mode | Xy precision helical gear transmission, Z imported brand screw drive |

Software working environment | Windows XP/7 |

Spindle power | 3.5kw4.5kw5.5kw (Optional) |

Driver motor | servo motor |

Working voltage | 220v380v (Optional) |

Engraving command | (G code) (nc), mmg, plt, eng, dxf |

Spindle rotating speed | 6000-24000rpm/min |

Control system | NC studio/DSP |

Product Detail

|

|

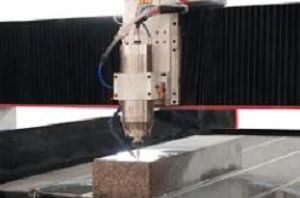

Economical Granite engraving machines are mainly used for light Granite. Suggest weight of granite less than 500kg | Heavy Granite engraving machines are mainly used for Heavy Granite. Weight of granite can more than 500kg |

| 5.5KW High Frequency Water Cooling Spindle (7.5kw for option) Machine comes standard with a 5.5kw high frequency water cooling spindle. And is fully programmable with speeds from 6000 to 24000 RPM. |

| The Electronics of the CNC Router All the electrical components are housed and wired in a electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools required. |

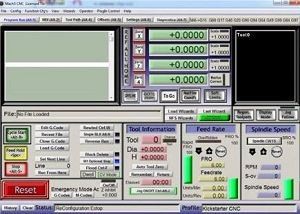

| MACH 3 Controller Mach3 is designed to control the CNC machine. The program is installed on a computer connected to the control machine. Mach3 was developed by American programmers, both for professional and amateur use, so it is the most common software for CNC machines in the world. Using Mach3, it is possible to control the following types of machines: turning, milling, routers, laser and plasma plotter, engraving. |

| Vacuum pump The machine comes with a 7.5kw vacuum pump for the sucking the stone, it is powerful enough for suck the machine on the table. |

Sample

Granite engraving machine can work on many materials like Marble, Granite, Artificial Stone, Terrazzo, Limestone, Sandstone, Travertine, Quartzite, Slate, Grindstone, Jade, Crystal, Glass, Acrylic, Wood, PVC, EPS Foam, Aluminum composite panel, Aluminum block, Copper and so on.

Application: Marble Granite Stone Roman Columns Corbel Pilasters Cylinders Pillars...

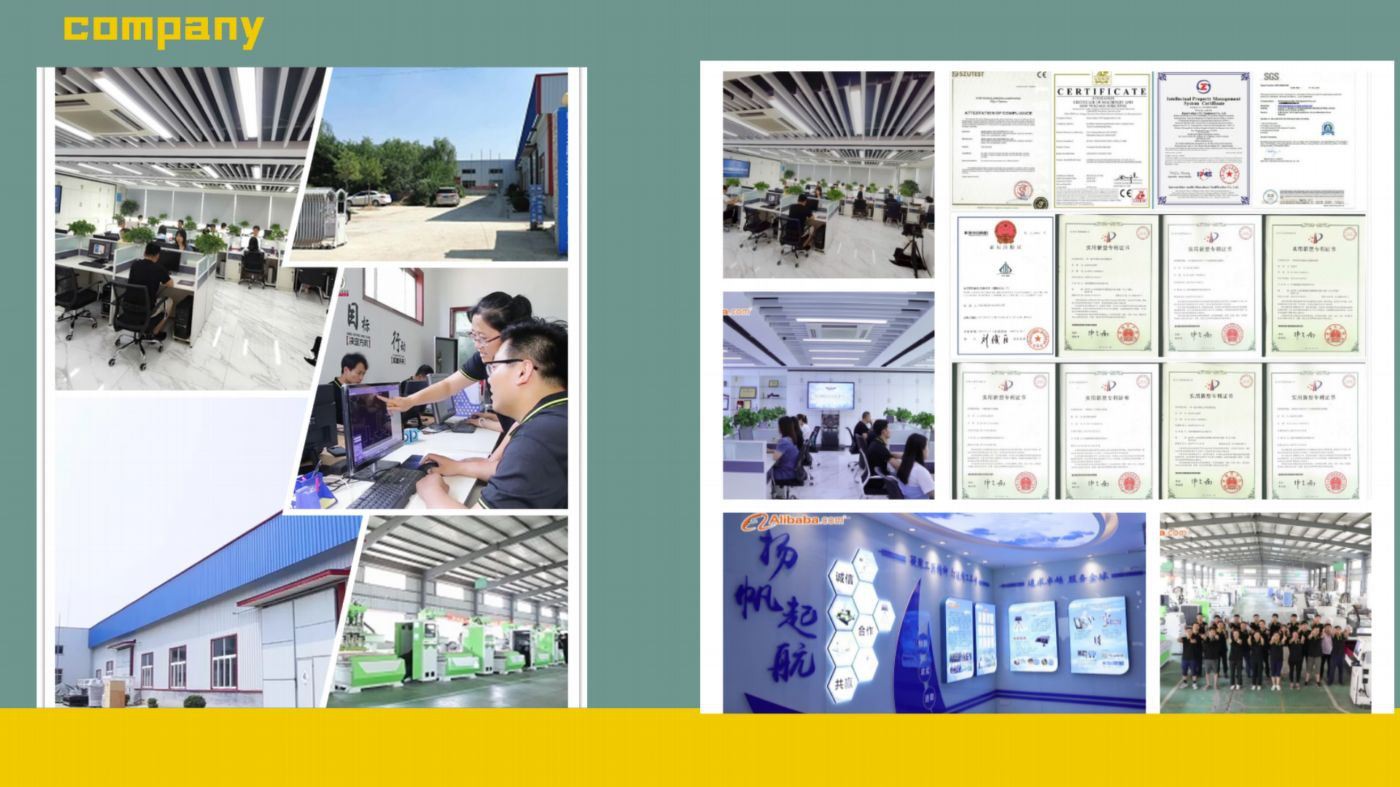

Company

Shandong Guandiao CNC Equipment Co., Ltd. is a professional CNC machinery company.

Since its establishment, the company has always put research and development as its top priority. From the initial barrier to continuous innovation, product personnel work tirelessly, focusing on the research and development of CNC machinery technology, and have achieved fruitful results in design and technology. A number of national patents. The company has a variety of products, can provide complete solutions according to user needs, and create unexpected value for users. It is a leader in the domestic panel furniture production equipment manufacturing industry. We have helped many users save labor, improve efficiency and gain a competitive advantage. The user has switched from a stand-alone mode to a more powerful assembly line production, laying a solid foundation for the operation of an unmanned factory for customized furniture in the future. Excellent quality, keep improving. The company invested heavily in the introduction of large-scale high-end CNC five-face milling machines, equipped with multiple vertical machining centers, laser interferometers, spheres and other advanced processing equipment and testing equipment. The product quality is equivalent to the international advanced level. The company plans to improve the intelligent production line of panel furniture and continuously develop new product lines in accordance with market demand to lay a solid foundation for the company′s long-term development.

Our products include woodworking CNC router, stone CNC router, wood lathes, edge banding machines, panel saws, laser machines, etc. We can produce a variety of CNC machines, woodworking processing centers, automatic tool change and other large-scale engravings according to customer requirements machine. And we can accept orders according to customer requirements.

We adhere to the management policy of "quality first, service first, continuous improvement, innovation to satisfy customers", and "zero defect, zero complaint" as the quality goal. In order to improve our services, we provide quality products at reasonable prices. Sincerely provide good service to customers at home and abroad. Warmly welcome customers to contact us!

Shipping

FAQ

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3: How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4. If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and skype.

Q5. Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6. What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7. MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Our Service

1. Sample testing before shipment

2. Provide 2 days free training for each machine

3. 12 months warranty for each machine

4. Friendly English version manual and operation videos for studying

5. Free technical support by phone, email, chatting or remote

6. Engineers available to service machinery overseas

Hot Tags: granite engraving machine, China, suppliers, manufacturers, factory, price, wholesale, for sale, Stone CNC Cutting Machine, CNC Stone Engraving Machine, Stone Engraving Machine, Stone CNC Router, Jade Cutting Machine, Stone Cutting Machine