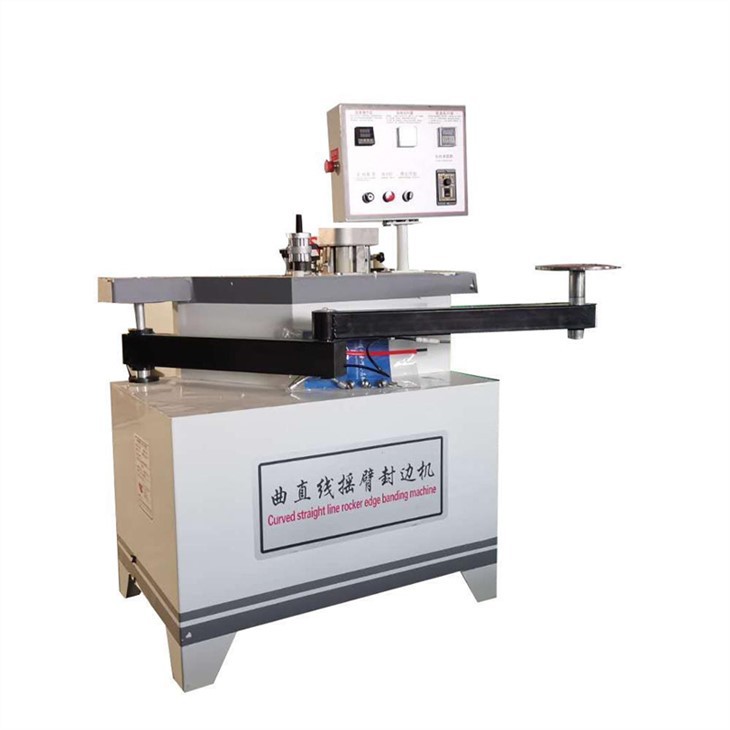

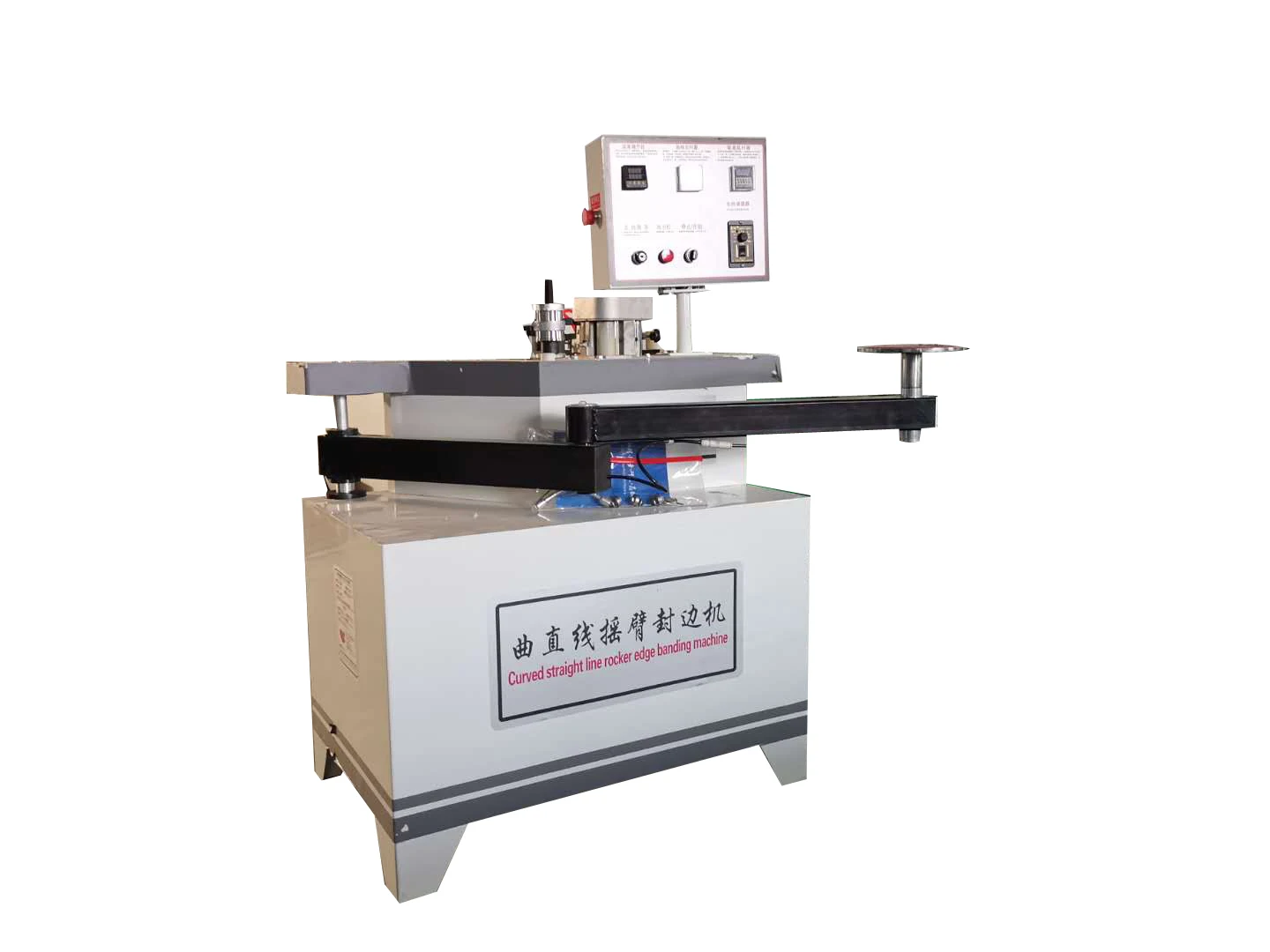

Production Introduction

| Name | Automatic polishing, sealing and repairing machine |  |

| Power Of Trimming Machine | 800w | |

| Power Of polishing Machine | 100w | |

| Self-running motor | 60w | |

| Feeding motor | 25w | |

| Voltage | 220v | |

| Left and right width strip size | 50cm | |

| sealing side height | 10-60mm | |

| sealing side thickness | 0.3-3mm | |

| Feeding speed | 0-6m/min | |

| Transport speed | 0-15m/min | |

| sealing side shape | line/Curve | |

| GW | 80kg | |

| Machine size | 120*54*72cm |

| The edge banding machine has the difference between the curved line edge banding machine and the straight line edge banding machine. From the perspective of market demand, the manual type is more suitable for small and medium-sized furniture factories, with low price, convenient operation and easy maintenance. The products sold in the market include machines in Italy, Japan, Taiwan and mainland China, which are divided into two categories according to their manufacturing principles: That is, the glue tank type and the lower glue tank type, the former drives from top to bottom, the glue tank is on the top, the latter drives from the bottom to the top, and the glue tank is on the bottom. The former is followed by the latter, and its characteristics are: 1. No glue leakage. Due to the transmission of the lower glue tank, if the sealing ring is damaged, it will cause glue leakage, which will affect the normal operation of the machine. There is no glue leakage problem in the glue tank. 2. The sol does not age. The lower glue tank has the problem of repeated heating and aging of residual glue, which affects the bonding quality. The sol in the upper glue tank seeps from top to bottom without precipitation and residue. 3. Easy to clean. Regular cleaning of the machine, the gluing tank is more convenient than the lowering gluing tank, and it can even be cleaned without stopping the machine without affecting the production. 4. Less failure. The upper transmission gear is convenient for refueling and reduces failures. For example, the MD-516A curved and straight edge banding machine produced by Qingdao Xicheng Woodworking Machinery adopts a stepless variable speed motor, which brings a lot of convenience to the user to use the machine. |

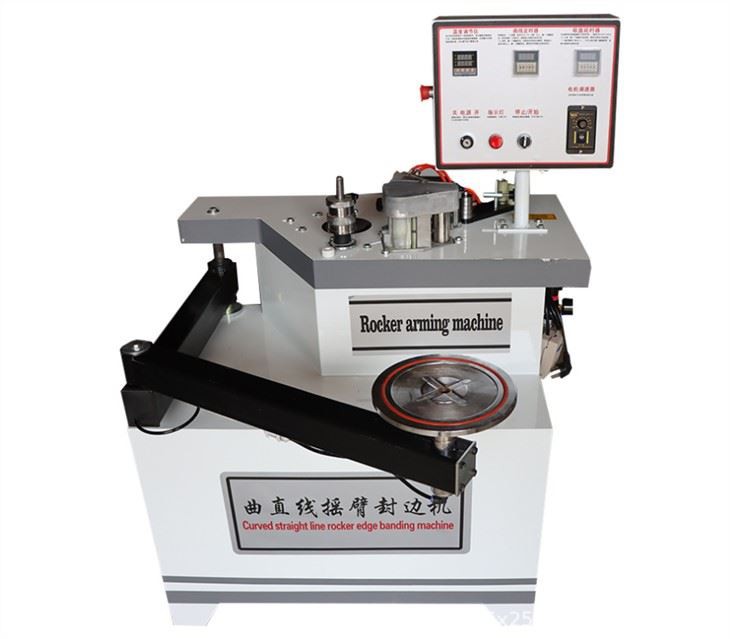

Mechanical Detail

|  |  |

|  |  |

FAQ

Q1: What is the warranty for the machine?

For our woodworking machine, we have 18months warranty.

Q2:Can I choose the Plug?

Yes,we have 220V/440V/380V for your choice,and 1phase,3phase,50hz and 60hz

Q3.What is your lead time after i pay?

Normally,we have stock for the machine,only customized for voltage ,about 7days or 15days.

Q4:How long will i get the machine after i pay?

The machine will deliver by sea to your port.about 20~55days arrival.

Q5:Is it OK to print my logo on the product?

Yes.Please inform us formally before our production and confirm the design firstly for the mass production.

Q6:It is my first time to purchase goods from china,how do i do?

Do not worry,Aucox/Woodfung has 10years export experience to all over the world,

also has professional sales team,we also have agent in Russia,Algeria,Pakistan,Peru,Vietnam,etc.

Q7:How to pack the machine?

we use wooden box to packge the machine to protect them to be safe

Q8.I do not know chinese,will the operation panel in english or spanish or other?

Yes,all our machine are with Chinese and English,If you want only English or Spanish or other,

we also can customize to you,but lead time will be a little longer.

Hot Tags: curved straight rocker edge banding machine, China, suppliers, manufacturers, factory, price, wholesale, for sale, Manual Edge Banding Machine, Portable Edge Bander